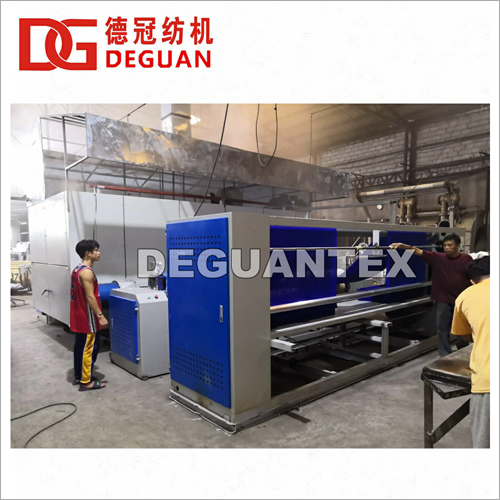

Stenter Machine

Stenter Machine Price And Quantity

- 185000.00 - 278000.00 USD ($)/Set

- 1 Set

- 185000 USD ($)/Set

Stenter Machine Trade Information

- Tianjin Port

- Western Union, Letter of Credit (L/C), Telegraphic Transfer (T/T)

- 20 Set Per Year

- 90 Days

- Contact us for information regarding our sample policy

- Standard Package

- North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- All India

- ISO9001,CE,SGS

Product Description

Stenter Machine isbroadly applauded for its excellent performance, easy maintenance,simple installations and high work efficiency. It is mechanicaldevice which is used for stenching fabrics in the textile industries.It helps to bring the perfect length as well as width for heatsetting applications. Stenter Machine is also utilizes for applyingan outstanding finishing chemicals in various shades of assortedadjustments. This unit is integrated with automatic heat recovery,exhausted fans, tensile rollers, air circulating fans and otheressential tools.

- The Heat Setting Stenter Machine is used for cotton/chemical fiber/mixed knitted woven fabric in open width status.

- According to the width size of the fabric, we can offer the following models with different normal work width:

- DGLD2400/2600/2800,which are popular sales according to customer's usage.

- The machine is equipped with horizontal rollers, single padder, mechanic weft straightener. All parts and components are applied some famous brand in order to keep excellent quality.

The specification of Stenter Machine

| Origin | China |

| Year of manufacture | 2019 |

| Main Matching Fabric | open width fabric (70~350g/m²) made of cotton, cotton/ polyester, wool, synthtic fiber and other blended fibers |

| Heat source | natural gas/oil/steam |

| Stentering type | Hot air circulating |

| Holding type | Pin +clip |

| Chain type | Pitch 60mm,oil-free lubricated |

| Rail type | Carbon steel+polymer wearing strip |

| Working type | Horizontal return chain |

| Working width | 1000-3600mm |

| Working speed | 5-60m/min |

| Chamber Nos | 2-12 |

| Chamber width | 3000mm |

| Insulating board thickness | 150mm |

| Temperature of chamber | 100~220ºC |

| Pinning & brush overfeed ratio | -20%~40% |

| Temp.& Breadth adjustment type | Adjust on each chamber respectively |

| Equipment Detail: | Single Padder/Schneider component/ Siemens motor,PLC,Touch Screen, Inverter/ EL Cutter/ Hankfeuer Burner |

| Capacity of machine | 61.5kw+22.75kw*chamber*Nos |

| Standard machine power supply | 380V/3P/50HZ |

| Control power supply | 220V/24V |

| Steam specification of steam box | 3-6kg/cm² |

| Steam consumption of steam box | 100-150kg/h |

| Compressed air | 0.35-0.6MPa |

| Total weight | 14T+5.8T/chamber*Nos |

Advantage:

- We possess the upgrade and design ability with our professional technical team, your customized design could be changed into drawing.

- With advanced technology and best quality, we make sure that you can get satisfied products based on our pleasant cooperation.